Fundamentals of Software Implementation

By David J. Piasecki; CPIM

By Hope Rachel Hetico; RN, MHA

Dr. David Edward Marcinko; MBA

www.HealthcareFinancials.com

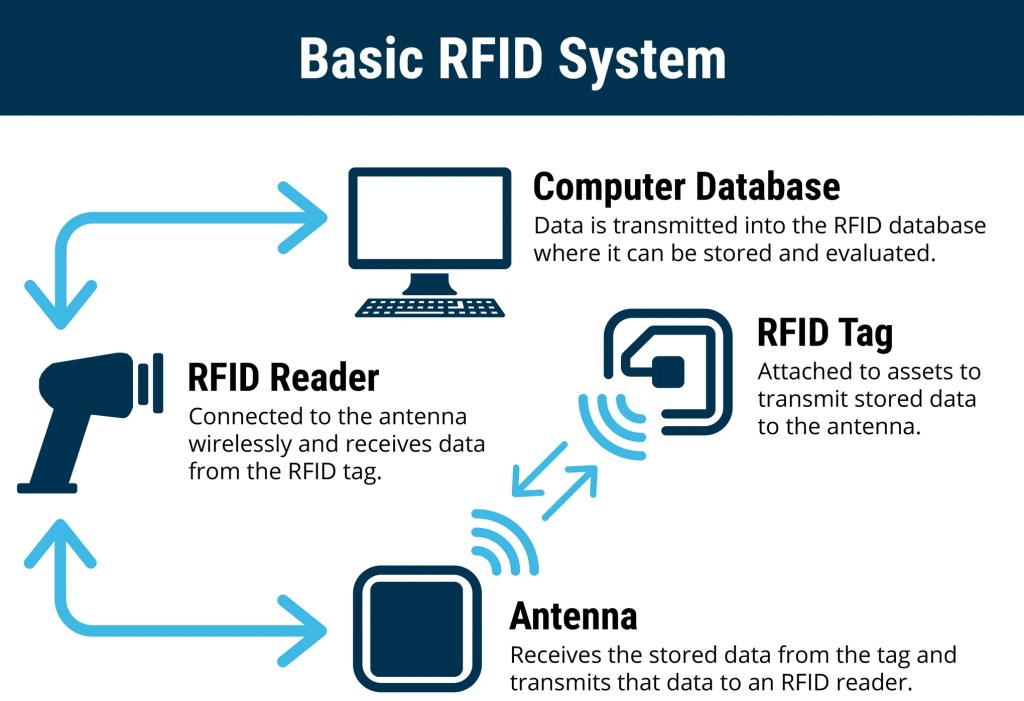

The singular focus of any Hospital Materials Management Information System (HMMIS) is to deliver significant improvements in the ability of hospital facilities, networks, and other healthcare organizations to optimize the processes and work flows associated with materials management systems and reduce the costs related to inventory, durable medical equipment, pharmaceuticals and supply chain management (SCM).

Understanding Strategies

Strategically, hospitals must exploit contemporary technologies and connectivity with suppliers and trading partners to:

- improve patient care and safety,

- increase efficiency,

- drive down costs, and

- optimize inventory levels.

Software Implementation

As with the selection process written about previously, ERP software implementation may also require outside assistance. Whether you use consultants from the software vendor, a business partner, or an independent firm, the implementation plan will likely be the same. It’s very important to listen to consultants and be prepared to dedicate the resources outlined in the implementation plan. A common mistake made by healthcare entities going through their first major implementation is to underestimate the complexity of their operations, the extent of system setup and testing, and the impact the implementation will have on their operation.

ERP Implementation

Here is an outline of a common scenario in single-hospital ERP implementations.

- The consultants warn of the consequences of not dedicating adequate resources.

- Management publicly agrees but privately thinks the consultants are crying wolf.

- Implementation fails or goes poorly.

- Management claims “how could we have known?”

Don’t let this be you. The only thing to assume about the implementation is that it that it will be much more difficult than expected, it will take longer than you expected, and it will cost more than expected.

Like most other projects, the success of a software implementation will be based upon the skill of the people involved, training, planning, and the effort put forth. Plan to have the most knowledgeable employees heavily involved in the system setup and testing.

Testing Programs

Adequate time should be dedicated to make sure every aspect of every process is thoroughly tested. An example of a detailed testing program is listed below:

- Does the purchase order [PO] receipt screen have all the information needed to perform the receipt such as vendor item number, item description, unit of measure?

- What happens when we receive more than the PO quantity?

- What happens when we receive less than the PO quantity?

- What happens when we enter multiple receipts against the same line?

- What happens if someone tries to change the PO quantity after we have entered a receipt?

- What happens if one changes the PO quantity at the same time we are entering a receipt?

- What happens when we reverse a receipt?

- What happens when we reverse a receipt after it has been paid?

- What happens if the ordered unit of measure is different from the stocking unit of measure?

- What happens when we receive an early shipment?

- What happens when we try to receive against a cancelled PO?

- What happens when we change the receipt location?

After the system has been thoroughly tested, employee training begins. Remember, dealing with unexpected issues is the norm; you don’t also need to be training employees after the system is supposed to be operating.

Hands-On Training

The training should consist of hands-on training and include written procedures for the tasks performed. For most positions, make sure that each employee has entered the equivalent of at least a full day’s transactions during the training. Using an actual day’s transactions is a good way to make sure the variety of transactions an employee is likely to encounter have been experienced. The most common mistake made in training is a lack of adequate repetition. Just because someone was able to perform the task once, during a training session on a Saturday three weeks prior to “going-live” does not mean they will be able to perform the task with system start-up. If they have repeated the task many times over a series of training sessions, they are much more likely to remember how to do it.

Assessment

Watch the data. During and immediately after the implementation it is incredibly important to watch the data and make sure everything is working as planned. Monitor the status of orders, purchase orders, and delivery orders paying specific attention to “stuck orders” or other exceptions. Conduct some aggressive cycle counting of fast-moving items to make sure transactions are working correctly.

Conclusion

So, tell us what you think about your hospital’s SCM software implementation? Feel free to review our top-left column, and top-right sidebar materials, links, URLs and related websites, too. Then, be sure to subscribe to the ME-P. It is fast, free and secure.

Get our Widget: Get this widget!

Our Other Print Books and Related Information Sources:

Practice Management: http://www.springerpub.com/prod.aspx?prod_id=23759

Physician Financial Planning: http://www.jbpub.com/catalog/0763745790

Medical Risk Management: http://www.jbpub.com/catalog/9780763733421

Healthcare Organizations: www.HealthcareFinancials.com

Health Administration Terms: www.HealthDictionarySeries.com

Physician Advisors: www.CertifiedMedicalPlanner.com

Subscribe Now: Did you like this Medical Executive-Post, or find it helpful, interesting and informative? Want to get the latest ME-Ps delivered to your email box each morning? Just subscribe using the link below. You can unsubscribe at any time. Security is assured.

Link: http://feeds.feedburner.com/HealthcareFinancialsthePostForcxos

Sponsors Welcomed

And, credible sponsors and like-minded advertisers are always welcomed.

Link: https://healthcarefinancials.wordpress.com/2007/11/11/advertise

Filed under: Information Technology | Tagged: david marcinko, David Piasecki, DME, durable medical equipment, ERP, HIT, HMMIS, hope hetico, IT, SCM, supply chain management, www.healthcarefinancials.com | 1 Comment »