Engineering and Medical Work Practice Controls

By Patricia A. Trites; MPA, CHBC, CHCC, CMP™ (Hon)

Dr. Charles F. Fenton, III; JD, FACFAS

Hope Rachel Hetico; RN, MHA, CMP™

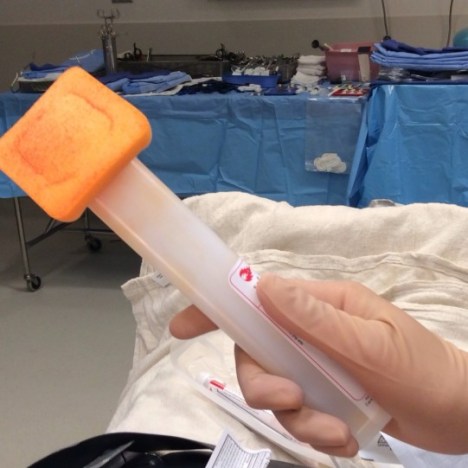

Engineering and medical practice controls are methods used to isolate or remove bloodborne pathogen hazards from the workplace. These practices should be used to eliminate or minimize employee exposure by removing the hazard or isolating the employee from the exposure. However, where occupational exposure remains after institution of these controls, personal protective equipment [PPE] must be employed, as described below.

Engineering Controls

Engineering controls can be described as those an employer purchases and makes available to protect his or her employees. Examples are sharps containers, eye-wash stations, spill-kits, and safer needle systems. It is the employer’s responsibility to implement and maintain a system for ensuring engineering that controls are used. The engineering controls must be examined and maintained or replaced on a regular schedule to ensure their effectiveness. Conducting only an annual review of the engineering controls is inappropriate under the OSHA Standard.

Healthcare Work Practice Controls

Unlike engineering controls, healthcare work practice controls depend upon the behavior of the employee to reduce exposure. Examples are hand washing, utilizing universal precautions, and wearing appropriate PPE. Even with properly implemented work practice controls, exposure can still occur. Some of the engineering and work practice controls that must be addressed (if applicable to the specific healthcare organization) within the employee control plan [ECP] include:

- hand washing facilities and practices,

- treatment of sharp instruments,

- separation of food from contamination,

- certain procedures in the treatment of contamination,

- sterilization, and

- care of equipment.

Assessment

These engineering controls must be examined and maintained or replaced on a regular schedule to ensure their effectiveness. Conducting only an annual review of the engineering controls is inappropriate under the OSHA Standard.

Conclusion

How has OSHA affected your practice? Or, is it so 1999?

Your thoughts and comments on this ME-P are appreciated. Feel free to review our top-left column, and top-right sidebar materials, links, URLs and related websites, too. Then, subscribe to the ME-P. It is fast, free and secure.

Speaker: If you need a moderator or speaker for an upcoming event, Dr. David E. Marcinko; MBA – Publisher-in-Chief of the Medical Executive-Post – is available for seminar or speaking engagements. Contact: MarcinkoAdvisors@msn.com

OUR OTHER PRINT BOOKS AND RELATED INFORMATION SOURCES:

- PHYSICIANS: www.MedicalBusinessAdvisors.com

- PRACTICES: www.BusinessofMedicalPractice.com

- HOSPITALS: http://www.crcpress.com/product/isbn/9781466558731

- CLINICS: http://www.crcpress.com/product/isbn/9781439879900

- ADVISORS: www.CertifiedMedicalPlanner.org

- BLOG: www.MedicalExecutivePost.com

- FINANCE: Financial Planning for Physicians and Advisors

- INSURANCE: Risk Management and Insurance Strategies for Physicians and Advisors

Filed under: "Doctors Only", Glossary Terms, Health Law & Policy, Practice Management, Quality Initiatives, Risk Management | Tagged: bloodborne pathogens, Charles Fenton, ECP, eye-wash stations, hand washing, hope hetico, OSHA, Patricia Trites, personal protective equipment, PPE, safe needle, sharps containers, spill-kits | 3 Comments »